It’s been a minute.

Not because we ran out of ideas. Not because brewing “got boring.” It’s the opposite. Social media is exhausting, and at some point it became obvious: The noise wasn’t making the beer better. So we stepped back, put our heads down, and did the work.

And somewhere in that stretch, we cracked the code on the best beer we’ve produced to date.

Not “pretty good for homebrew.” Not “great when it’s fresh.” I’m talking world-class sensory, repeatable, and dialed in.

THE HIATUS

A large focus in the past year(s) has been consulting.

That’s where the real sharpening happens—different systems, different constraints, different water, different fermentation behaviors, different packaging realities. You see patterns fast. You also get humbled fast. Both are useful.

The result: we’ve been refining what matters and stripping out what doesn’t. Less tradition for tradition’s sake. More cause-and-effect.

METHODS & PROCEDURES

Let’s get this out of the way:

The core methodology is still the same as the updated Methods page/paper. The foundation is solid. The “why?” hasn’t moved.

What has changed is the execution—sequence, timing, and the level of control over the variables that actually swing flavor. Some procedures were simplified. Some were tightened. Some were replaced entirely because better tools and better data made it obvious we could.

Same compass. Cleaner map.

If you’ve been following TMB for years, you’ll recognize the direction. If you’ve only seen the internet’s watered-down version of these methods, just know: The devil is still in the details, and the details are where the beer gets made.

THE PRIVATE YEAST BANK: NOW APPROACHING 20 STRAINS

The yeast bank has quietly become one of the most important things we do.

We’re sitting at nearly 20 strains now, and the collection is getting… interesting. Some are modern tools for modern styles. Some are historical artifacts that simply don’t exist in the commercial world anymore. Some are serial-repitched “house” cultures that have taken on a personality of their own.

Here are a few additions/highlights:

TMB TRIPPY — HAZY YEAST

This one is exactly what it sounds like: modern, expressive, and built for that saturated fruit profile that people chase in hazies. But we’re applying it the TMB way—clean process, controlled fermentation, and flavor intensity without the sloppy edges.

TMB-312 “Seveřan” — NORTHERN CZECH

Banked in the 1970’s from a pre-capitalistic-merger northern Czech brewery.

Attenuates well with good flocculation. Classic cold fermentation. Clean, crisp, and honest.

Recommended for cleaner Czech lager styles. Because of the age of the culture, there are no comparable modern strains. This is the kind of yeast that reminds you why “heritage” matters when it’s real.

TMB-313 “Južan” — SOUTHERN CZECH

Originates from a brewery in the south of Czechia and is well-suited to classic Czech lager.

It’s ideal for delivering restrained attenuation on decocted wort. It throws more esters and higher alcohols than most strains, but still produces low diacetyl.

Recommended for highly-characterful Czech lager—think “Budvar-like,” but in your own hands.

TMB-309 “PLASTIKZIEGE”

Taken directly from a tank sample of Ayinger Jahrhundert.

If you know, you know.

TMB 305.1 “HANOVER”

This one started its life as our own asylum… and then spent years pressure-fermenting over 100 lagers. I decided to rebank this serially repitched strain because it earned it. We’re still on the fence about epigenetic changes, but here’s what I’ll say: this yeast behaves like it’s become accustomed to high oxygen, high pressure, and high wort CO₂ content. Biomass accumulation is at least the same (I’d argue better) than a no-pressure ferment. It’s become a workhorse with a memory.

TMB 311 “PHOENIX”

A revived old pitch of OG 2206.

We had a hunch that 2206 changed around the pandemic. Reviving the old strain confirmed it. This is a reminder to everyone: your “favorite strain” is not always the same strain forever.

COMMUNITY: DISCORD IS THE DAILY, THE FORUM IS THE VAULT

Daily discourse heavily favors Discord now. That’s just reality. It’s fast, it’s active, and it’s where the banter and troubleshooting happen in real time.

The forum, meanwhile, has become what it probably should have been all along: A repository of methods, procedures, long-form writeups, and the deep technical threads worth saving.

And we’re still growing by the way. The number of professional brewers in the mix is no joke, and the bar keeps getting raised (in the best way).

Still having regular in person beer meetings from around the world! So truly unique and amazing.

Enjoy some photos.

BREWTOOLS + BRUCONTROL (BEHIND THE SCENES)

Yes, there’s been work happening behind the curtain.

We’ve been collaborating with Brewtools on some super cool stuff (another blog post forthcoming) and working on updates and bug fixes to BruControl. If you’re running modern systems and you care about control, reliability, and the ability to push process without babysitting it—this matters.

More to come on that when it’s time.

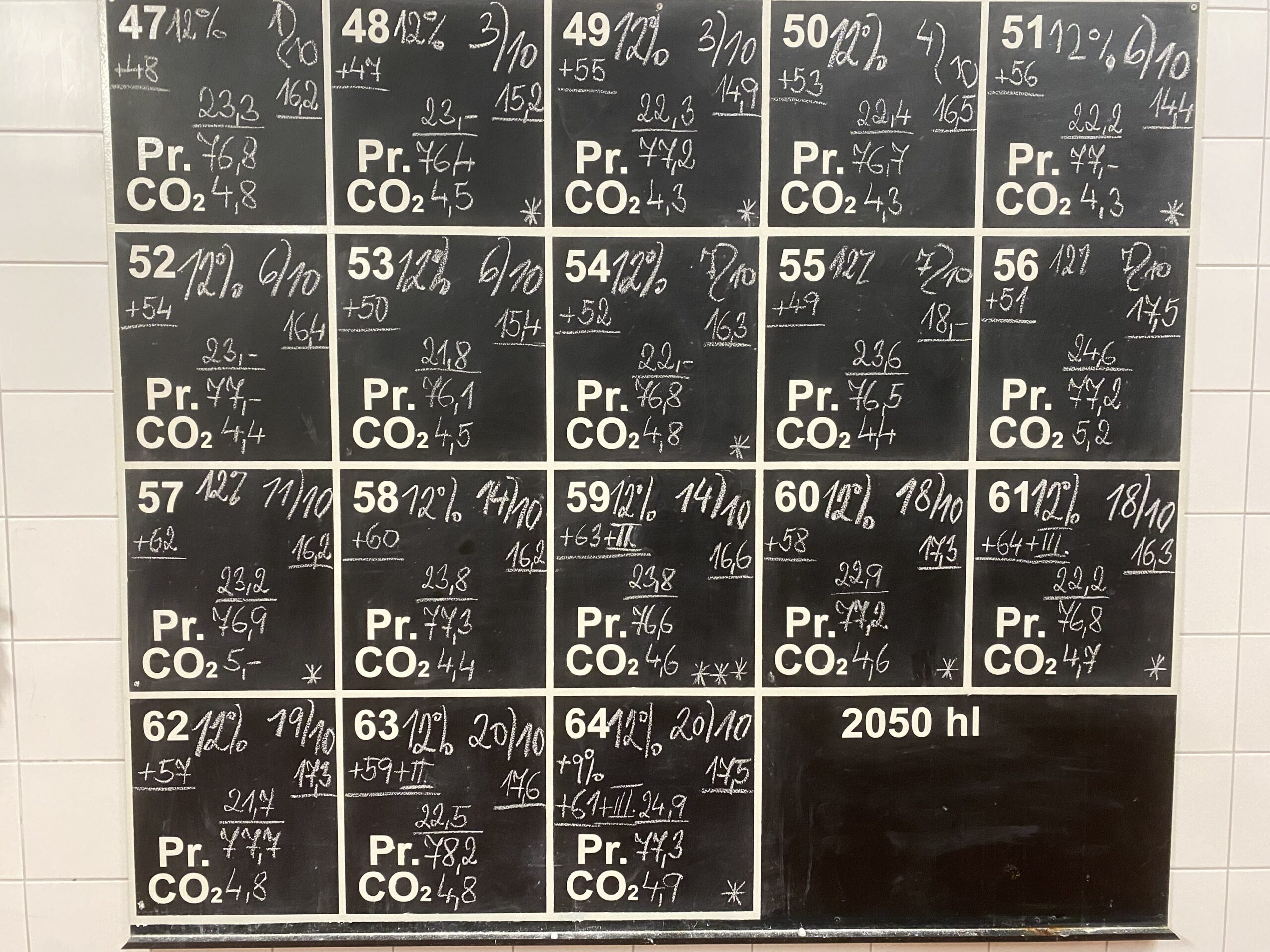

THE BIGGEST DISCOVERY LATELY: CO₂ CONCENTRATION DURING FERMENTATION

This is the one that’s been slapping us in the face:

CO₂ concentration during fermentation appears to be one of the largest influencing factors in beer sensory that we’ve seen to date.

Not “a factor.” Not “interesting.” A major lever.

Once you start controlling it—intentionally, repeatably, and with proper measurement—the beer starts changing in ways that are obvious even to people who aren’t nerds. Texture. Perceived bitterness. Aroma expression. “Crispness.” That last 10% that separates “clean” from “commercial.”

We’ll be digging into this harder this year. Expect real data, real process, and real results—because opinions are cheap and we don’t do cheap.

WHAT’S NEXT

This year we’re pushing brewing (and brewing science) forward with new discoveries, better measurement, and more controlled experiments.

More strains. More controlled fermentation work. More consulting lessons turned into repeatable process.

Most importantly I want to thank EVERYONE who makes this all possible. Here’s to more beer that makes you stop mid-sip and go: “Damn”

Prost